Flexa Performance Fresh Powder 6kg

New TPU with high strength and flexibility, ideal for use in gaskets, flexible joint covers,

vibration dampers and others where the strength of the flexible material is significant.

Properties:

- Very good tear resistance

- Excellent mechanical properties

- Resistant to repeated bending

- Chemical resistance

Applications:

- Shoe soles and insoles

- Elements of flexible covers in vehicles

- Seals

- Production tools

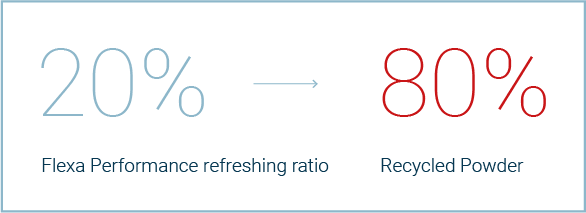

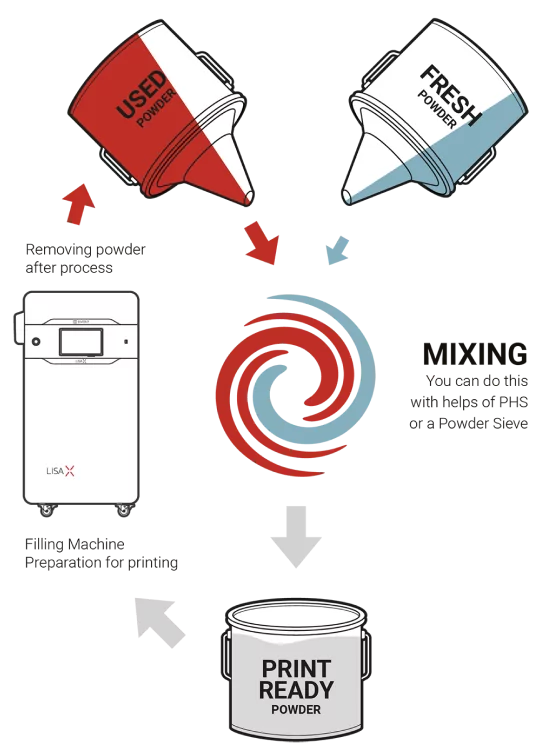

Reusing the powder in a simple and cost-efficient way

What is the refresh rate?

It is the ratio of a minimum amount of fresh powder needed in a mixture of material

used in an SLS 3D printer. A lower refresh ratio means better cost-efficiency of the material.rn

General information information

Method

Material type: TPU

Dedicated for: Lisa X

Software: Sinterit Studio Advanced

Material refreshing ratio¹: 20² %

Nitrogen needed: no

Color: light grey

Mechanical properties

Tensile Strenght (X direction): 7.99 MPa

PN-EN ISO 527-1:2012

Elongation at Break (X direction): 182.63 %

PN-EN ISO 527-1:2012

Shore Hardness in A scale: 88

PN-EN ISO 868:2005

Thermal properties

Softening point (Vicat, A50): 96 °C

PN-EN ISO 11357:2018

Melting point: 120-150 °C

PN-EN ISO 11357:2018

1. The refresh ratio is the amount of refreshing powder required to be mixed after a printing

with unsintered material. 2. Flexa materials have 100 [%] usability. Although to keep printout

parameters at optimal levels, we recommend adding 10% fresh powder for each new printrn 3.

Depending on printing settings and the designrnrnrnInformation provided within this document

shows values for reference and comparison only. Parameters presented in this specification

are subject to change without notice. Final part properties may vary based on a printed part

design and orientation, material handling as well as printing environment (humidity and

temperature). The manufacturer is responsible for validation whether the printout is accurate

and fit for the intended purpose.